Figure 15.17 shows a male thread cut by a die and terminating in a runout. A cut thread can be made by the use of a tap for female threads, or a die in the case of a male thread. Screw threads are produced by cutting or rolling. 15.16 illustrates a typical application where an internal thread terminates in an undercut.

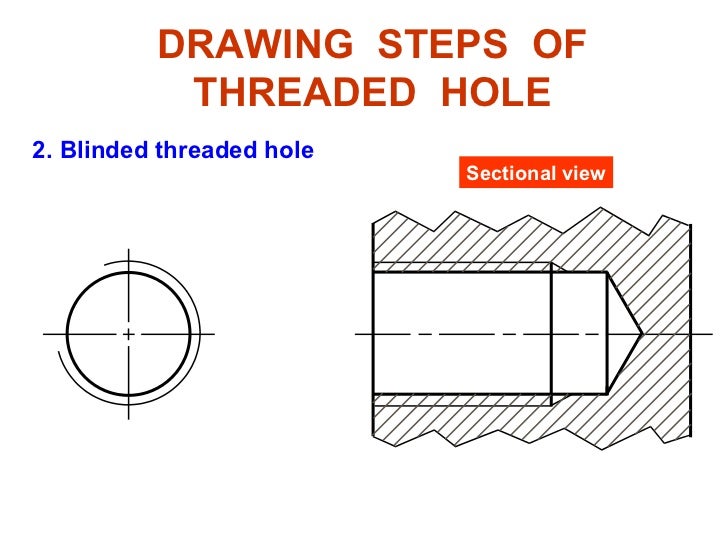

The projection of the major diameter is drawn by a continuous narrow line and the cross hatching extends to the minor diameter.Ī section through a sealing cap in Fig. Note that the projection of the major and minor diameters drawn as hidden detail will be indicated by dashed narrow lines.Ī section through the collar is given in Fig.

The tapered lines for incomplete threads are shown here for completeness of text.Ī female thread through a collar is shown in Fig. However, in 1984 the revised standard permitted the line to be omitted if there was no functional need. the line at 30° indicating the runout was the practice in BS 308:1972. Line thicknesses are indicated in the circles. The included angle left by the tapping drill is 120°. In the sectional elevation, the section lines drawn at 45°, continue through the major to the minor diameter. The effective length of the thread is again shown by parallel lines and the runout by the taper at 30° to the thread axis. Note that the minor diameter is drawn as a complete circle in the end elevation, the major diameter is broken and the different line thicknesses also help to distinguish the female from the male thread. The actual dimensions of the minor diameter for any particular thread size can be Tapping holeĪpproximated at 80% of the major diameter for the purposes of conventional representation.įigure 15.13 shows the convention for a female thread applied to a blind tapped hole in a sectional view. Line thicknesses are given for each part of the thread. The break in the inside circle distinguishes the end elevation of a male thread from a female thread.

The minor diameter of the thread is shown by parallel lines and in the end elevation the projected circle is not continuous. The thread runout along the shank of the stud is indicated by a line drawn at 30° to the thread axis. Figure 15.12 shows the convention for a male thread. Threads are so regularly used on engineering drawings that recognizable conventions are required to save draughting time.

0 kommentar(er)

0 kommentar(er)